Testing that Reaches the World

Battery EMC Testing

Welcome to our premier EMC testing services tailored specifically for the dynamic needs of the battery industry. At Clark Testing, we understand that ensuring the electromagnetic compatibility (EMC) of battery technologies is paramount to their success in today's increasingly interconnected world. With our cutting-edge facilities and expert team of engineers, we offer comprehensive EMC testing solutions that guarantee the reliability, safety, and compliance of your battery products.

Our state-of-the-art testing facilities are equipped with the latest instrumentation and technology to evaluate the electromagnetic emissions and susceptibility of batteries across a wide range of operating conditions. Whether you're developing lithium-ion, lead-acid, nickel-metal hydride, or other advanced battery technologies, our rigorous testing protocols are designed to identify and mitigate any potential EMC issues early in the development process.

Partnering with us means gaining access to a trusted ally committed to your success in the competitive battery market. With our fast turnaround times, personalized customer service, and industry-leading expertise, we ensure that your battery products not only meet but exceed regulatory requirements and industry standards. Trust Clark Testing for all your EMC testing needs and unlock the full potential of your battery innovations

Partnering with us means gaining access to a trusted ally committed to your success in the competitive battery market. With our fast turnaround times, personalized customer service, and industry-leading expertise, we ensure that your battery products not only meet but exceed regulatory requirements and industry standards. Trust Clark Testing for all your EMC testing needs and unlock the full potential of your battery innovations

Typical EMC/EMI Validation Testing for battery modules and battery packs include:

- RF Emissions

- RF Immunities

- Impedance

- Insulation Resistance

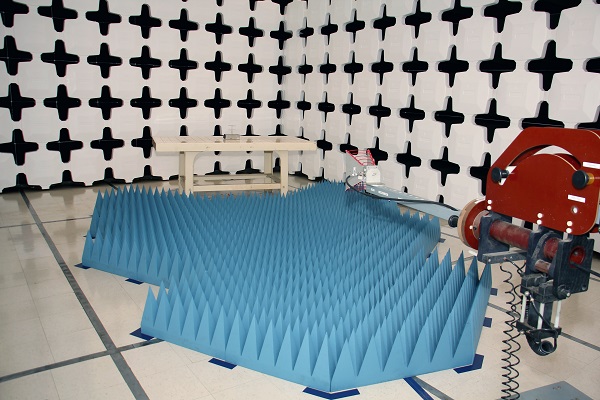

EMC Chamber Information

3 Meter

- Door size: 48"Wx84"H

- Max weight 2,000 lbs

Military Chamber (1 Meter)

- Door Size: 10' W x 12' H

- Max Weight 14,000

- Can fit cabinets up to 14 feet long.

Copper Shield Room

- Standard door size

- Miscellaneous uses

In-House Power Capability

- 4,160VAC (200A) 3-phase (Can be stepped down to various voltages using onhand or rental transformers)

- 480VAC (200A) 3-phase and single phase

- 230VAC (100A) 3-phase and single phase

- 120VAC (100A) single phase

- 300VDC (50A)

- 75/150/300HP variable frequency drives for speed control

Up to 400W resistive loads in various types and sizes